Lightweight Thermoplastic PVC and Polyurethane Monofilament Belting

Lightweight Thermoplastic belts offer solutions for a wide variety of specialized applications. Unique cover compounds and surface textures are offered for most conveying situations: cut and abrasion resistance, extreme temperature resistance, oil and fat resistance, sticky product release and FDA approved products. Thermoplastic belting includes a monofilament construction which offers cross rigidity along with a high degree of flexibility. We offer expert assistance in European-style belting.

Call us for current price and availability (951) 764-3678

Specifications

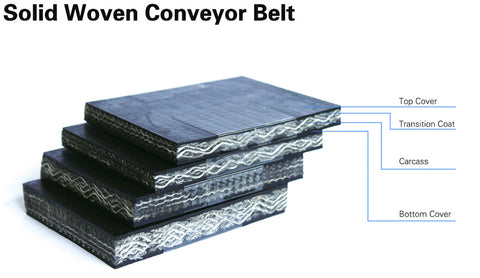

Carcass

Two basic carcass constructions make up the foundation of the belts offered.

- Cross-rigid fabrics utilizing monofilament and multifilament fibers to ensure the belt lays flat yet has maximum flexibility for small pulley capabilities.

- Multifilament warp and multifilament weft fabrics for troughing applications.

- Antistatic and non-antistatic types are also available.

Applications

A wide variety of thermoplastic belts are available for the various material handling needs in a broad range of industries, including:

- Food Handling

- Package Handling

- Paper Products / Corrugated Boxboard

- Metal Parts Conveying

- Textile Industry

- Electronic Parts Conveying

- General Industry

Covers

The Availability of different cover types enables you to match the most suitable compounds and surface with the demands of the product environment. Cover compounds and surface textures and offered for most conveying situations: FDA/USDA regulation, extreme temperature resistance, oil and fat resistance, cut and abrasion resistance, and sticky product release. The many advantages of polyurethane (PU) and polyvinylchloride (PVC) make them the ideal cover compounds for the most difficult material handling conditions. Special covers are available for the unique applications requiring a non-standard compound or surface. The versatility of the thermoplastic product line has earned it the reputation of being the problem solver, and it has increasingly become the belting material of choice for a growing number of conveying applications.

Profiles

Cleated and flanged belting. A tremendous variety of compounds and shapes are available for most every conveying situation.

Splicing Methods

Depending on the demands of a particular application, we offer many different splicing options. These range from the super-strong finger splices, finger-over-finger splices and soft splices to easy-to-install mechanical fasteners such as metal, plastic, and spiral lace.

Guides

Considerable experience in bonding and welding all types of guides and tracking strips. We can suggest the best match of guide and belt for your application.

Perforations

We can handle almost any customer need utilizing our steel rule dies, machined dies, waterjet, or CNC drilling technology. Basic to close tolerance requirements are handled easily and quickly.

Longitudinal Splicing

Although many specifications are immediately available up to 118" wide, our unique capabilities make us an industry leader in longitudinal splicing. Belts of almost any width are obtainable by splicing multiple belts side by side. The lap area is uniformly smooth with the belt cover.

Special Fabrication

The unusual is our specialty! Put our engineering know-how to work to solve the most troublesome conveying problems. Our in-house capabilities make us your source for "one-stop shopping" when designing that special system.

We Also Recommend